Project Description : Roller Rehab Bridge Bearing Service , 17-21 August, 2018. Bearing rust removal, cleaning, painting, greasing and oiling. Mark bearings to gauge future movement and report on service and any defects identified.

Bridge Bearing Descriptions.

This 18 span bridge has girder spans on each side of the river and three large trusses over the waterway. The girder spans have a standard slide plate bearing at one end of the girder and the accompanying fixed girder on the other. The flange on the bottom of the girder only allows lubrication in the crevice between girder and bearing. Once cleaned these were treated with a penetrating oil then greased. Within two days there was significant contraction of the girder (10mm) on Pier 9 (see images below). This would indicate that the cleaning and lubrication has had a positive effect on bearing function. No defects were apparent on the slide plate bearings themselves. Pier 6 and Pier 9 on the southern bank have crumbling bearing beds. These beds are very thin and would require, jacking of the bridge, entire removal of existing bed and injection of the new bed medium. There are a number of beds which have been partially repaired with a white resin. It would appear this was only applied to the outer bed, with the crumbling inner bed left as is. Pier 12 has a broken anchoring bolt on the bottom flange of the girder as depicted.

Truss Spans

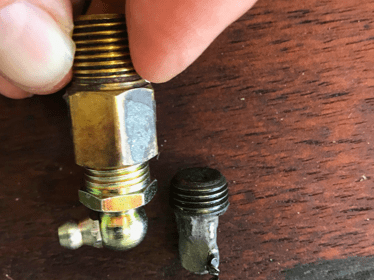

The Truss spans have a combination of fixed pivots at one end of the girder and a pivot with a sliding base component at the other end of the girder. The slide pivots have 4 grease nipples on each base plate. Each grease and stem has either a totally corroded nipple or totally blocked stem with old grease. Most of the ball bearings in each nipple were seized. These were removed and left in thinners to free them up. Some did some remained stuck. The grease in the top plate under the stem was still in good condition. The stems under the nipple were all removed and cleaned out. To allow proper greasing of the internals under pressure all the nipples will require replacement. Whilst the stems which screw into the base plate vary in thread pattern, the nipple thread in each is consistent. These will be replaced at the next visit. Once replaced these bearings will be greased internally.

BEFORE, slide plate bearings had some crevice rust and were very dry with no evidence of lubrication.

AFTER. Crevice rust removed between girder and bearing, painted, treated with penetrating oil and topped with grease.

EVIDENCE OF MOVEMENT. In two days both sets of bearings on Pier 9 had contracted approximately 10mm, which is significant movement for such a short span. These slide plate bearings may have been inoperable prior to servicing.

Bearing beds on piers 6 and pier 9 require total removal of the crumbling bed and bed replacement.

BEFORE AND AFTER, sliding pivots over the river.

All grease nipples require replacement as they are either corroded or inoperable.

All nipple stems were blocked they were all cleaned out within the bearing was evidence of good grease. They will be pumped under pressure when the nipples are replaced.

All nipples have a standard quarter inch BSP thread pattern.

Broken fixed end anchoring bolt on pier 12.

Recommendation.

- Replace all Grease nipples.

- Consider drilling and tapping in oil reservoirs on the bottom flange of the girders to lubricate slide bearings.

- Replace bearing pads on piers 6 and 9.